Are Recycled Plastic Bags Eco-Friendly?

2025-01-09

Recycled plastic bags are indeed more eco-friendly compared to traditional plastic bags. They are made from recycled plastic materials, which reduces the demand for raw materials and helps decrease plastic waste accumulation, thus having a lesser negative impact on the environment. Using recycled plastics helps reduce the amount of plastic waste and supports resource recycling.

However, while recycled plastic bags are more eco-friendly, they are still plastic products, and they still need to be properly recycled after use to avoid environmental pollution. Compared to single-use plastic bags, recycled plastic bags consume fewer natural resources during production and can be reused multiple times, making them a more sustainable choice.

The production process of recycled plastic bags involves several steps aimed at making eco-friendly bags from recycled plastic materials:

1. Material Collection and Sorting

Recycling Plastic: The production of recycled plastic bags begins with the collection of discarded plastic. Common materials include waste plastic bottles, plastic bags, packaging films, industrial waste, etc.

Cleaning and Sorting: The collected plastic is cleaned to remove impurities, grease, and contaminants. Then, the plastics are sorted by type to ensure proper treatment of each type of plastic.

2. Plastic Crushing and Shredding

The cleaned plastic is shredded into small granules or plastic fragments. This process is typically done using cutters or shredders, ensuring the fragments are evenly sized for further processing.

3. Extrusion and Melting

The crushed plastic granules are fed into an extruder, where they are heated and melted into a uniform plastic flow.

At this stage, the plastic flow is extruded into thin films or tubes, which will form the base material for the plastic bags.

4. Blow Molding or Stretching

Blow Molding: In the blow molding process, the molten plastic film is blown into the shape of a bag. This step is crucial in forming the bag, and it is commonly used for most plastic bag production.

Stretching: Sometimes, a stretching process is used to enhance the strength and toughness of the plastic film. The film is mechanically stretched to improve its tensile strength and durability.

5. Bag Design and Cutting

The plastic film is cut into the appropriate size according to the design requirements, forming the shape of the bag. This stage involves customization, including dimensions, bottom designs (whether gusseted or flat), and other features.

Additional features, such as self-sealing strips or zippers, may be added to the bags during this stage.

6. Printing and Decoration

If needed, environmentally friendly water-based inks are used for printing. This is typically done for brand promotion, product information, or design patterns. The printing process uses low-pollution, biodegradable inks to maintain the eco-friendly nature of the product.

7. Cooling and Finishing

The bags are cooled and set to ensure they do not deform or dissolve during use.

Afterward, the bags are organized, folded, and packaged, ready for distribution and sale.

8. Quality Control and Inspection

Quality control is crucial during production. Manufacturers inspect the thickness, strength, seal quality, and appearance of the bags to ensure they meet standards and can effectively protect items.

9. Packaging and Distribution

Finally, the completed recycled plastic bags are rolled, folded, or packaged into larger bundles for transportation and sale.

Environmental Benefits during Production:

Reduced Raw Material Use: By using recycled plastics, the reliance on new resources is reduced, which helps alleviate environmental burden.

Energy Savings and Emission Reduction: The production process using recycled materials consumes less energy compared to using new plastic, thus reducing carbon emissions.

Waste Reduction: The recycled plastic waste is transformed into useful packaging materials, reducing the accumulation of waste.

In conclusion, the production of recycled plastic bags, using discarded plastic as raw material, employs various eco-friendly processes aimed at reducing the consumption of natural resources and effectively lowering environmental pollution. This process aligns with modern sustainable development requirements and is well-suited for widespread use in the packaging industry.

For sample or more packaging customization needs, please contact us

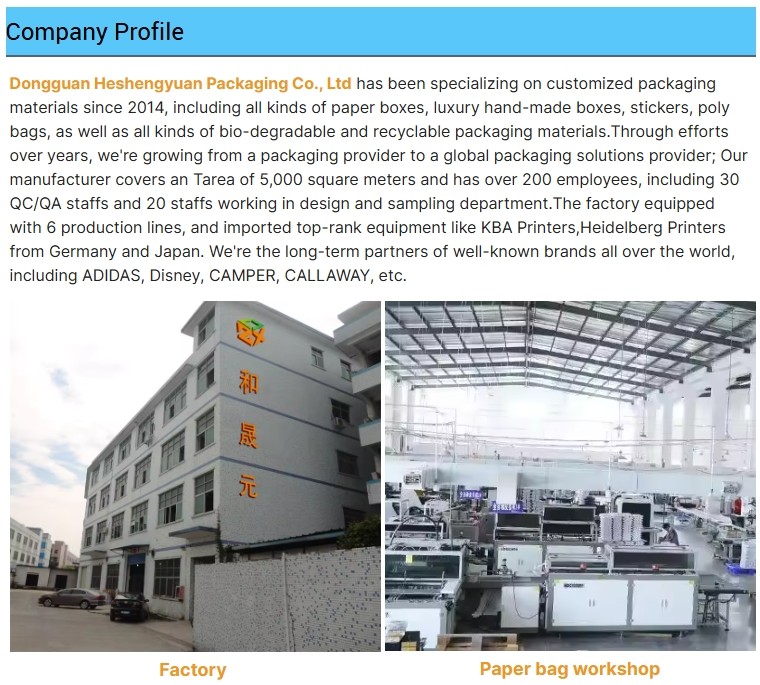

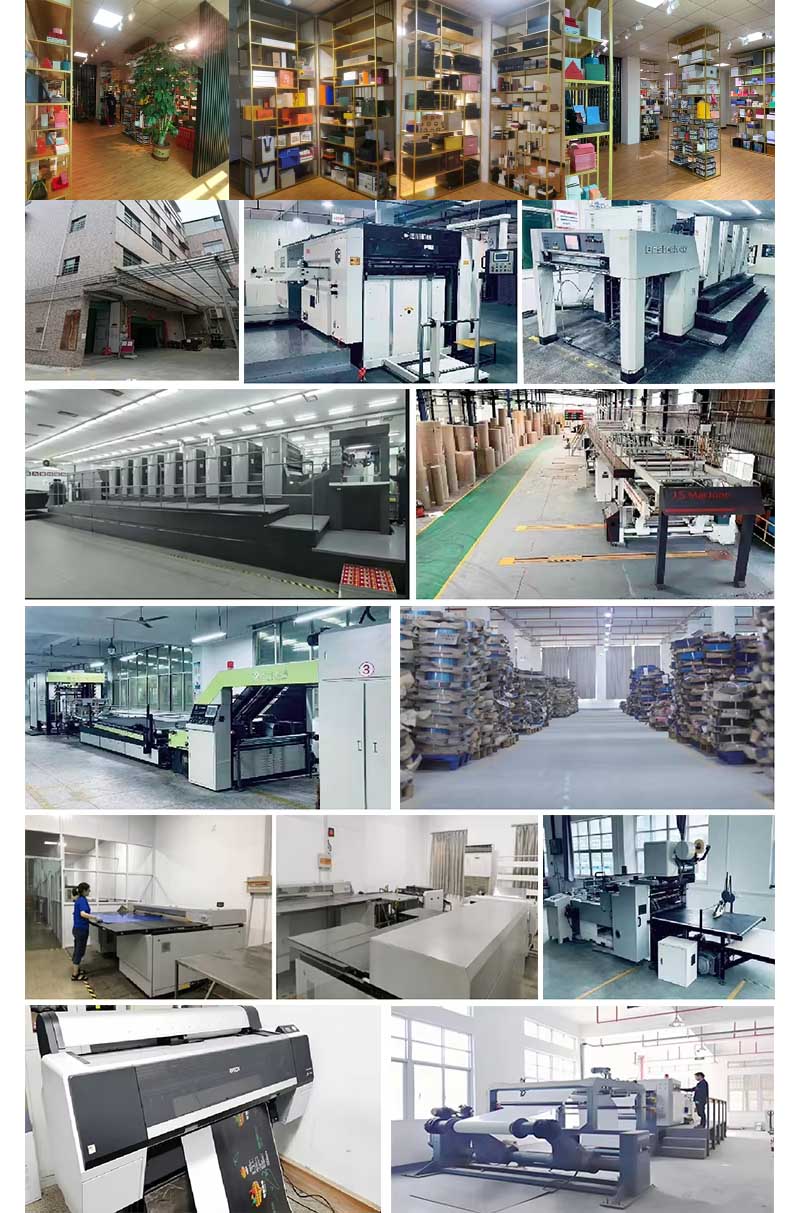

About us

Zeal X’s Recycled plastic bags with Bottom offer full customization and a one-stop packaging solution. Our product range includes various types of boxes, high-end handmade boxes, labels, plastic bags, and a variety of biodegradable, recyclable packaging materials. Our products are certified by GRS, FSC, REACH, BHT, and more.