Do you know how paper boxes are produced?

2025-01-10

The production process of paper boxes involves several steps, from raw material preparation to the final packaged product. Here is the main process of paper box production:

1. Raw Material Preparation

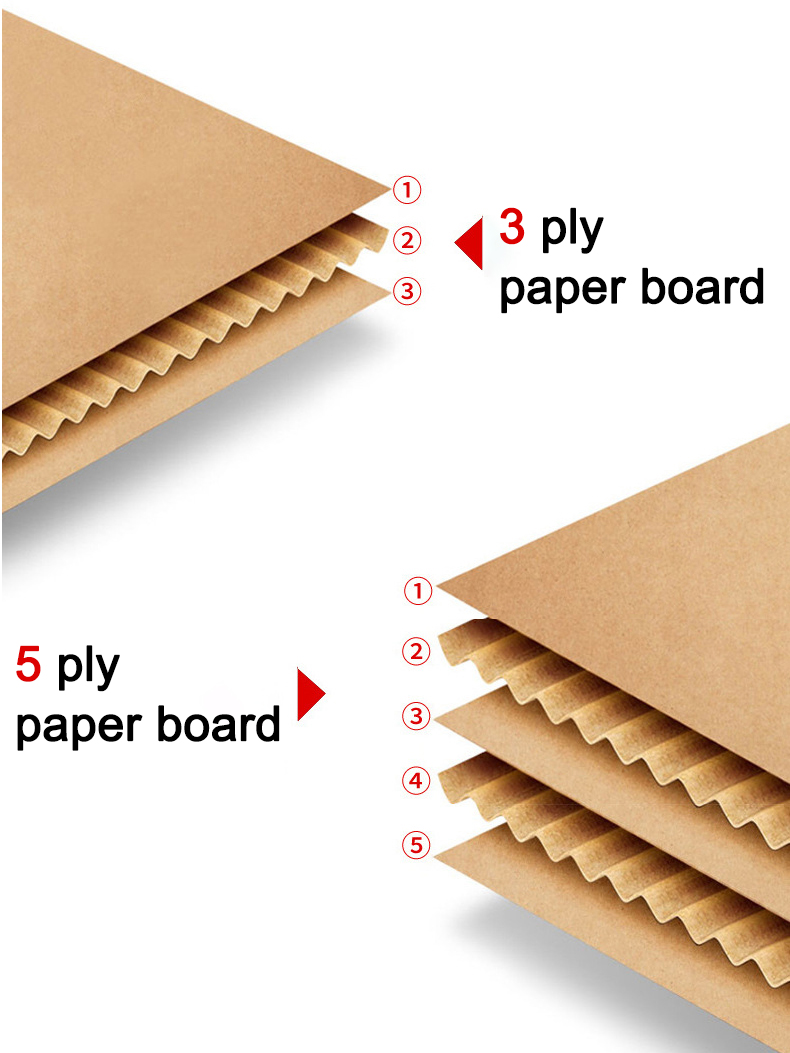

The main material for paper boxes is paperboard, typically made from a mix of recycled paper and wood pulp. The type of paperboard used depends on the required strength and purpose, including single-layer, double-layer, or corrugated paperboard. The raw materials are first cleaned and treated to remove impurities, ensuring the quality of the paperboard.

2. Paperboard Manufacturing

Paperboard is produced through a wet paper-making process. First, the raw materials are mixed with water to form paper pulp. The pulp is then mechanically pressed to form paperboard, which is dried and compressed to become solid sheets. Different layers and structures of paperboard can be produced based on specific requirements.

3. Corrugating Process (for Corrugated Boxes)

For corrugated boxes, the paperboard undergoes a corrugating process. A corrugating machine uses heat and pressure to transform the paperboard into a wavy shape, increasing the strength and compression resistance of the paperboard. Corrugated paper typically comes in different types, such as A, B, C, and E, with variations in wave size, suitable for different packaging needs.

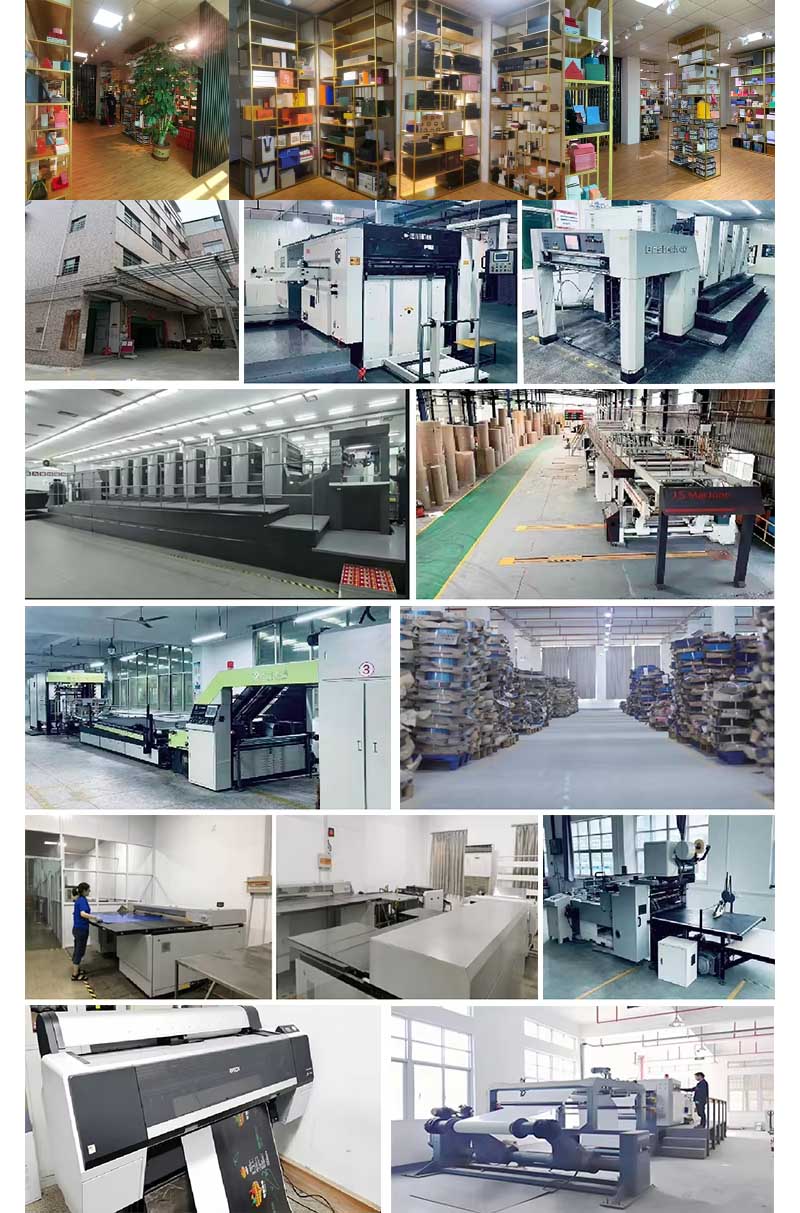

4. Cutting and Printing

Next, the paperboard is cut and printed. The paperboard is cut into the desired box shapes according to the design. Meanwhile, a printing machine is used to print patterns, text, branding, and other information on the surface of the paperboard. Common printing methods include offset printing, flexographic printing, and digital printing.

5. Folding and Gluing

After cutting and printing, the paperboard moves to the folding and gluing stage. In this process, the paperboard is folded along predetermined lines to form the box shape. Then, glue, hot-melt adhesive, or pressure bonding is used to bond the parts of the paperboard together, creating the final box structure.

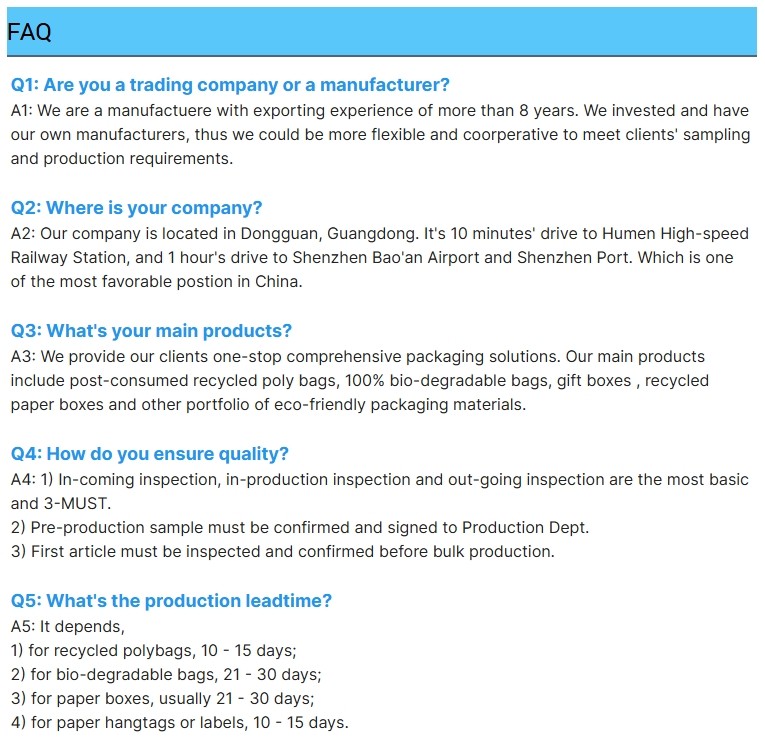

6. Quality Inspection

During production, the paper boxes undergo quality checks to ensure they meet the required standards. Inspections typically focus on the box's strength, dimensions, print quality, and adhesive bond.

7. Packaging and Shipping

Finally, the qualified paper boxes are sorted, folded, or packed and prepared for storage or distribution, ready to be shipped for further use.

Environmental Benefits of the Production Process:

Resource Recycling: Using recycled paper and renewable materials reduces the need for raw resources and lowers the environmental impact.

Waste Reduction: Paper boxes are recyclable, and waste materials from the production process are often reused, reducing overall waste.

Overall, the production of paper boxes is simple and eco-friendly, and they can be customized based on customer needs. Paper boxes are widely used in consumer product packaging, logistics, and gift packaging across various industries.

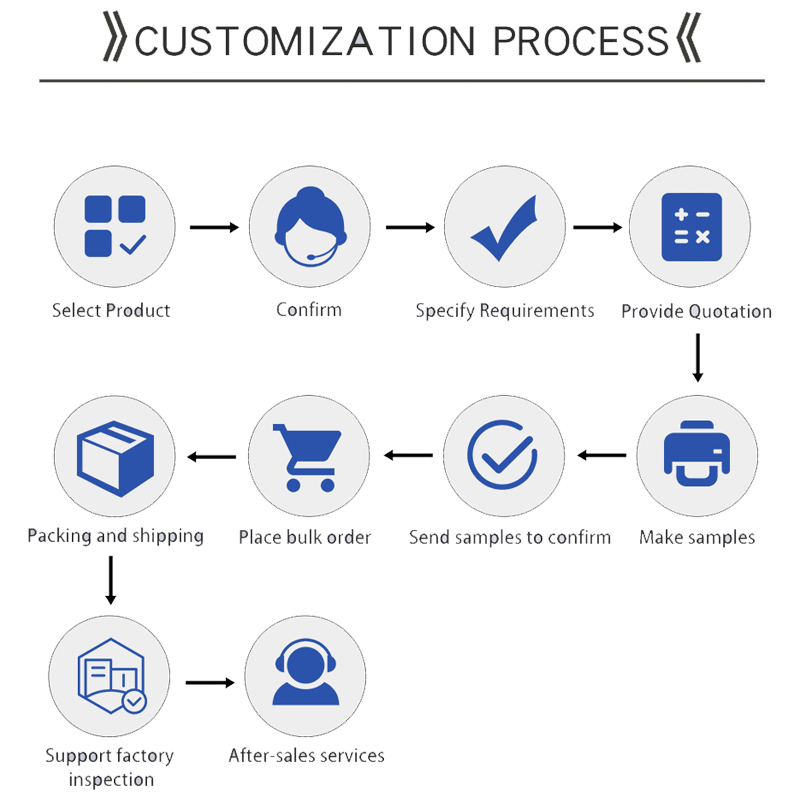

For sample or more packaging customization needs, please contact us

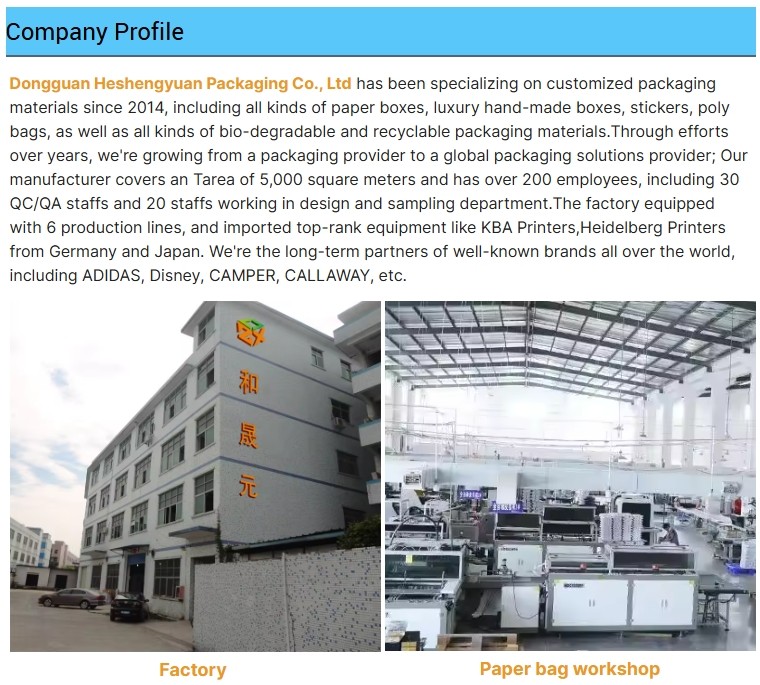

About us

Zeal X’s eco-friendly paper boxes offer full customization and a one-stop packaging solution. Our product range includes various types of boxes, high-end handmade boxes, labels, plastic bags, and a variety of biodegradable, recyclable packaging materials. Our products are certified by GRS, FSC, REACH, BHT, and more.